Apparel Manufacturing Facility for OEM & Private Label Brands

In-house production, skilled workers, and strict quality control for global brands

Get StartedWhy Choose Us as Your OEM Partner

Delivering quality, reliability, and manufacturing control for your brand

We are a professional OEM garment manufacturing facility with over 14 years of experience in producing high-quality apparel for global brands. Our factory integrates in-house production lines, skilled workers, and strict quality control systems to ensure consistent results from sampling to bulk manufacturing.

As your long-term OEM partner, we specialize in custom apparel manufacturing, supporting both small batch orders and large-scale production. From pattern development and fabric sourcing to cutting, sewing, finishing, and packaging, all key processes are handled within our manufacturing facility, giving you better control over quality, cost, and lead time.

Our production team focuses on precision manufacturing and efficiency, allowing us to translate your designs into reliable, production-ready garments. We offer flexible OEM solutions tailored to your brand’s positioning, target market, and growth stage.

With a strong commitment to ethical manufacturing and compliance, our facility operates under internationally recognized standards. Every order goes through multi-stage quality inspections to ensure workmanship, measurements, and materials meet approved specifications before shipment.

Production Departments

Specialized facilities covering every stage of garment production

Sewing Workshop

Our sewing workshop is a core part of our in-house apparel manufacturing facility, equipped with advanced industrial sewing machines operated by experienced technicians.

This department handles a wide range of OEM garment manufacturing requirements, from basic stitching to complex construction for jackets and performance apparel.

By keeping sewing fully inside our factory, we maintain consistent quality, efficient production flow, and stable lead times for bulk orders.

Pattern Room

The pattern room plays a critical role in our OEM manufacturing process.

Our pattern makers are responsible for pattern development, grading, and size optimization to ensure accuracy before production begins.

This in-house capability allows our garment factory to support custom designs, fit adjustments, and scalable production for different markets and size ranges.

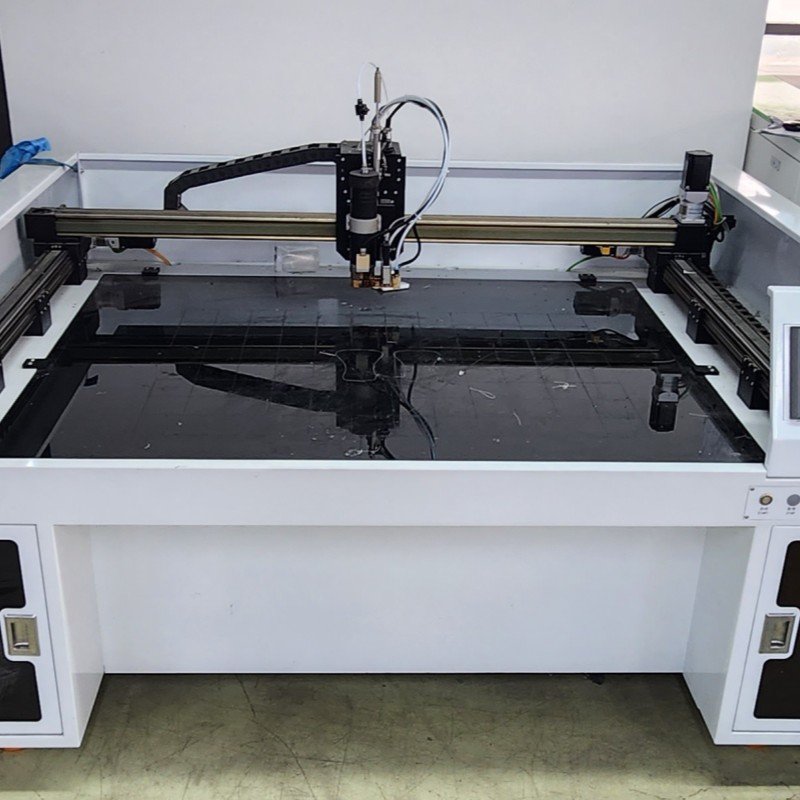

Cutting Department

Our cutting department uses automated and precision cutting equipment to ensure fabric accuracy and minimize material waste.

As part of our apparel manufacturing facility, this department supports various fabric types and complex layouts required in OEM apparel production.

Precise cutting is essential for consistent quality across bulk manufacturing, especially for structured garments.

Finishing Department

The finishing department is responsible for trimming, inspection, ironing, and preparation before final packing.

This stage ensures every garment produced in our OEM factory meets approved specifications for appearance and workmanship.

By controlling finishing processes in-house, our manufacturing facility reduces defect rates and improves overall production consistency.

Embroidery Workshop

Our embroidery workshop supports branding and customization for OEM apparel manufacturing.

With multi-head embroidery machines, we can handle logos, patches, and detailed designs required by private label brands.

Keeping embroidery inside our garment factory ensures accurate execution, color consistency, and reliable turnaround times.

Printing Department

The printing department provides multiple printing techniques including screen printing, heat transfer, and digital printing.

As part of our integrated manufacturing facility, this department allows us to handle custom branding directly during production rather than outsourcing.

This gives OEM clients better control over quality, durability, and production schedules.

Quality Inspection

Quality inspection is a key part of our OEM manufacturing system.

Our garment factory follows a multi-stage inspection process, including in-line checks and final inspections based on approved standards.

Every product is reviewed to ensure materials, measurements, and workmanship meet production requirements before shipment.

Packaging & Warehouse

Our packaging and warehouse department manages final packing, labeling, and storage for bulk orders.

As part of our apparel manufacturing facility, this department ensures orders are packed according to client specifications and prepared efficiently for shipment.

Integrated warehousing allows better inventory control and smoother logistics coordination.

Machinery & Equipment

Our manufacturing facility is equipped with specialized machinery for cutting, sewing, printing, embroidery, and finishing.

Continuous investment in equipment allows our OEM garment factory to handle diverse product categories and maintain stable production capacity.

This machinery foundation supports both small batch development and large-scale manufacturing.

These OEM services are fully supported by our in-house manufacturing facility, ensuring consistency, quality, and production control.

OEM Services & Solutions

Comprehensive manufacturing support for your brand success

OEM Full Package

- Complete garment production from concept to delivery

- Fabric and trim sourcing based on your specifications

- Quality control and inspection

- Private label and branding services

Technical Support

- Pattern grading and marking

- Sample development and prototyping

- Tech pack interpretation and execution

- Material recommendation and sourcing

Product Expertise

- Casualwear and streetwear collections

- Workwear and corporate apparel

- Athletic and performance wear

- Children's and youth clothing lines

Value-Added Services

- Custom embroidery and printing solutions

- Garment washing and finishing treatments

- Third-party quality auditing support

- Consolidation and direct-to-retailer shipping

Certifications & Compliance

Industry-recognized standards ensuring quality and ethical production

ISO 9001:2015

WRAP Certified

OEKO-TEX Standard 100

BSCI Compliance

GRS Certified

SEDEX Member

We maintain strict compliance with international labor standards, environmental regulations, and product safety requirements.

View All Certifications Details →